What Is A Metal Roofing Gauge: 22, 24, 26, 29 and more

Metal roofing has become more popular for good reasons: durability, long-term use, and even aesthetics. But homeowners and even contractors who are considering a metal roof should pay close attention to what is known as roofing gauge, the thickness of the metal roofing material. This parameter of the material determines in large part how strong the metal roof will be, its resistance to weather and how it will perform over a long period of time.

A Guide To Roof Gauge is something that will impact how well your roof stands up to wind, hail, and heavy snow. This blog will explain what metal roofing caliber is, and how to choose the right one for you.

What is a Metal Roofing Gauge (GA.)?

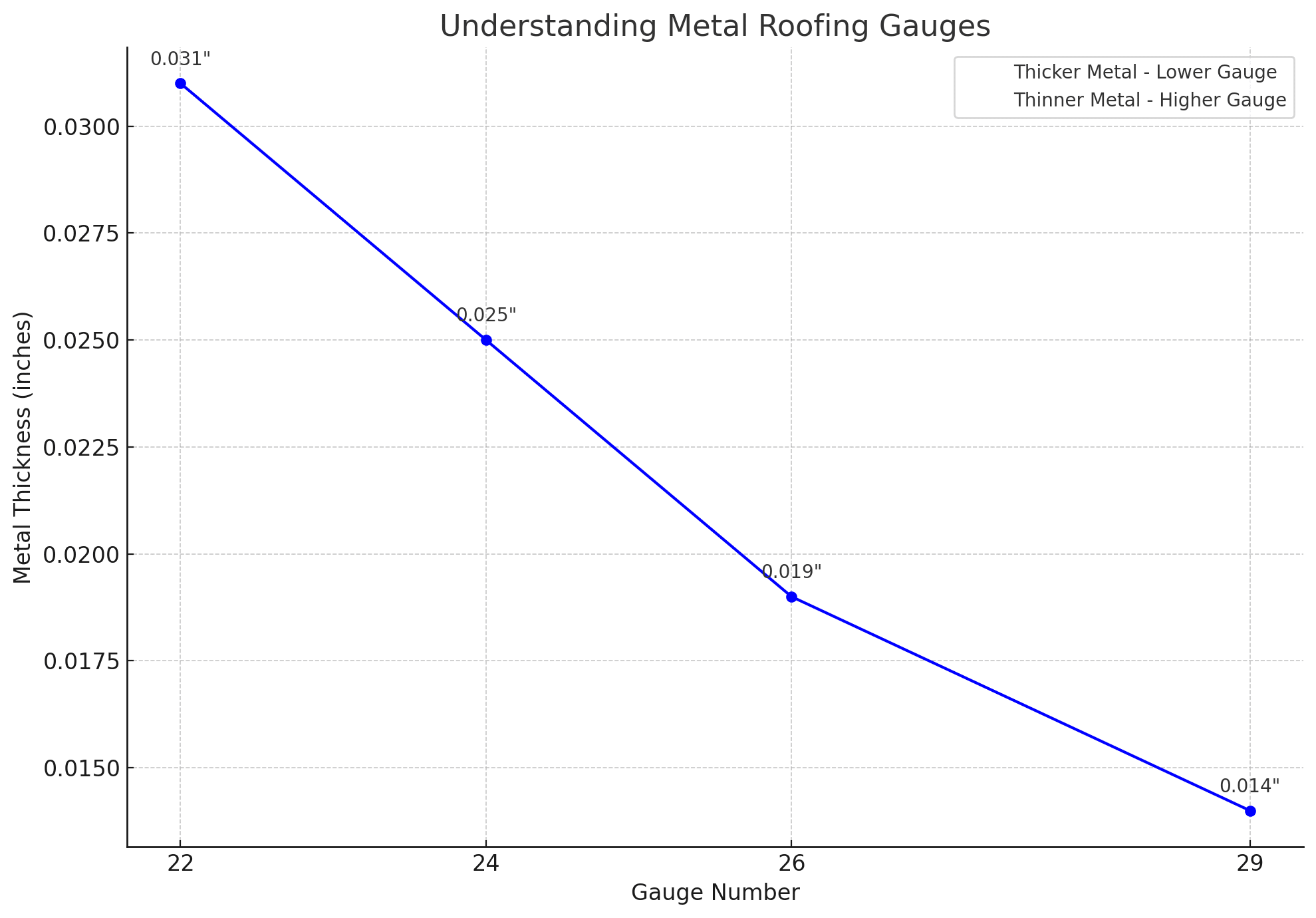

In this system, the lower the numbered caliber, the thicker the sheet of metal. A 22 GA. is much thicker than a 29 GA. This is important for roofing because the thicker the metal, the more structural integrity it provides – the less likely to be damaged by impact or severe weather conditions.

Thickness of the metals affects performance as well as budget. Thicker shingles sometimes cost more than a typical product, but will offer more protection. On the other hand, thinner, less expensive shingles might be better for a smaller budget, but wouldn’t be suited for a large building.

- Lower GA. = thicker metal (e.g., 22-gauge)

- Higher GA. = thinner metal (e.g., 29-gauge)

Metal thickness impacts both durability and cost.

History of Metal Gauging Systems

History of Metal Gauging Systems

The metal gauge system has its origins in the 19th century, during the Industrial Revolution, when the need for standardized measurements in metal production became essential. As manufacturing processes evolved, different industries, particularly steel and wire manufacturing, required a reliable system to measure the thickness of metals used in construction, machinery, and infrastructure.

Initially, various regions and manufacturers used different measurement systems, which created confusion and inefficiencies. The gauge system was introduced to standardize these measurements, allowing producers and buyers to communicate more clearly. The system was based on the number of operations or steps a metal sheet had to go through to reach its final thickness. As a result, lower gauge numbers indicated thicker sheets, as they required fewer passes through rolling mills, while higher gauge numbers corresponded to thinner sheets.

Over time, the American Wire Gauge (AWG) system emerged as the standard for measuring wires, while Birmingham Gauge (BG) and Stubs Iron Wire Gauge were used for sheet metal and iron. The transition from using inches or millimeters to the gauge system allowed manufacturers to improve accuracy and consistency in metal thickness, regardless of the material being used—whether steel, aluminum, or other metals.

While the gauge system has been a long-standing standard, modern advancements in manufacturing have also incorporated more precise measurements like millimeters and inches, particularly in regions outside North America. However, in industries like roofing, construction, and machinery, the gauge system remains a vital reference point, especially for metal sheets. The enduring use of the gauge system shows its importance in maintaining uniformity and reliability in metal production worldwide.

Common Gauges Used in Metal Roofing in 2024

Many calibers are used in roofing. The most commonly used sizes in residential and commercial 22, 24, 26 & 29. Each grade has unique properties suiting it to different buildings and climates.

- 22: This is the thickest and most robust metal roofing option, typically used in buildings such as warehouses and on structures where there is a risk of severe weather.

- 24: One of the most popular residential and commercial building choices for its strength and durability.

- 26: The standard commercial gauge: a good intermediate that provides both strength and value.

- 29: the thinnest option that’s typically used in less extreme climates and buildings where cost is more of a priority.

Gauges by roofing types:

- 22: Best for industrial and high-impact areas

- 24: Ideal for high-end residential and commercial use

- 26: Standard residential roofing choice

- 29: Affordable option for mild climates (Toronto, Niagara etc.)

In the diagram above, we display the gauge thicknesses for standard steel, which is what the chart represents. However, it’s important to note that the thickness of a given GA. can vary depending on the type of steel. For example, galvanized steel is often slightly thinner for the same grade compared to standard steel due to the coating process. This means that for the same GA., galvanized steel will have a thinner actual thickness.

For instance, at Professional Metal Roofing, the metal roofing panels made of galvanized steel are 0.53 mm thick, which corresponds to 26 gauge. This demonstrates how these numbers can differ in GA. across different steel types.

Read more: Metal Roofing Sheets – Types, Prices & Where to Buy

Applications of 10, 12, 16, and 18 Calibers Steel

10 Gauge Steel (0.1345 inches)

Whereas 10 Gauge Steel (0.1345 inches) – one of the thickest metal sheeting in the construction and industrial processing is also known as the strongest. It is not uncommon to find 10 caliber steel used in devices that are subjected to an unusual level of stress or impact, such as military tank armor. This type of steel would not be used as a rooftop sheeting as it is too heavy and thick for that application.

Common Applications:

- Structural support beams in buildings and bridges

- Industrial machinery and equipment housing for added protection

- Agricultural equipment, such as trailers, plows, and other heavy machinery

- Shipbuilding for hulls and other large components

- Heavy-duty enclosures for electrical and industrial purposes

12 Gauge Steel GA. (0.1046 inches)

12 gauge steel is slightly thinner than 10 GA. and is extremely strong for its weight. It’s mainly used in heavy construction and industrial applications. It is easier to work with than 10 thickness, but its thickness is strongly discouraged for roofing applications.

Common Applications:

- Automotive industry: used for manufacturing truck beds and chassis components

- Industrial shelving and racking systems, where high weight loads need to be supported

- Strong metal doors and security enclosures

- Structural framing for large-scale projects, such as warehouses

- Fencing and high-security gates

16 Gauge Steel thickness (0.0598 inches)

At 16 gauge steel, you still get a good balance of strength and workability, and it’s appropriate for a large number of industrial and construction uses. That said, 16 GA. is generally not strong enough for roofing applications, but it does common use for interior and non-structural applications.

Common Applications:

- Metal studs and framing systems in commercial construction

- Metal furniture, including desks and cabinets

- HVAC ducts and ventilation systems

- Light-duty trailers and transportation vehicles

- Automotive parts, such as brackets and panels

18 Gauge Steel thickness (0.0478 inches)

18 thickness steel is even thinner than 20 gauge and is often used for ‘light’ duty applications where structural strength is desired, but flexibility still remains a priority. It is often used in consumer and commercial products but isn’t used in roofing.

Common Applications:

- Appliance manufacturing, such as refrigerators, washing machines, and dishwashers

- Metal cabinetry and furniture used in kitchens and offices

- Decorative architectural elements, such as trim and paneling

- Fencing and window security bars for residential properties

- Electrical enclosures for housing and protecting wiring and components

These lower-gauge steels do not suit the lighter, more decorative uses required by roofing, but they are an ideal match for heavy, high-strength uses in industry for structural support, machinery and equipment.

Read more: 5 Advantages of Metal Roofing in Toronto’s Climate

Thicker vs. Thinner Metal Roofing

The heaviest steel roofing thicknesses, such as 22 and 24, are optimal for areas with cold or severe weather conditions, heavy snow, hail storms, high wind, or other harsh climate factors. They will stand up better to these elements and avoid denting and warping when subjected to extreme climatic conditions. It is an excellent way to protect your home from Mother Nature. A gauges of 22 or 24 are also most appropriate to be paired with metal roof panels that have clips for the installation. These are the heavy-duty choices in metal roofing, more cost-intensive, and the heaviest gauge that will be added to your home.

Thinner gauges like 26 and 29 are cheaper and easier to install, as they’re lighter in weight. They’re also better suited to milder climates with infrequent extreme weather events. Those thinner calibers aren’t going to prevent someone from kicking in a door, but they’re still plenty tough for many residential applications.

- Thicker gauges = more durable, better for harsh weather

- Thinner caliber = more affordable, easier to install

Choose based on climate, building structure, and budget.

Read more: Metal Roof Installation: DIY vs. Professional Help

How to Choose the Right Metal Roofing Gauge

Typically, lower gauges are recommended for areas with high winds, heavy snow, and/or frequent hail, while homes in mild climates can frequently select a higher caliber.

Additionally, the kind of structure, whether residential or commercial, may be a consideration as well. Commercial buildings typically are of a thickness for strength and longevity as well, so it’s always a good idea to ask the roofing professional which gauge is best for your application.

- Consider climate: harsher weather like in Northern Ontario (Barrie, Thunder Bay etc.)requires lower gauge

- Budget: thinner diameter are more affordable

- Building type: commercial buildings may require thicker metal

Read more: 10 Key Differences Between Standing Seam and Corrugated Metal Roof

Common Misconceptions About Roofing Gauges

A homeowner can easily be confused by several myths about metal roofing gauges. One popular misconception is that a lower GA. is always better, i.e., thicker is better. However, thicker metal may not necessarily be better. While some regions require the extra strength, others do not. Thinner metal can easily meet the requirements of a mild climate homeowner, so you shouldn’t pay more than necessary.

Another difference is the GA. of the metal. But higher gauges are not inferior in quality: they are simply thinner, lighter and more flexible – sometimes to the advantage of the roof, depending on the environmental and structural needs.

- Lower caliber doesn’t always mean better

- Higher caliber doesn’t mean lower quality

Metal Gauge and Cost Considerations

The thickness of the metal is responsible for a portion of your roofing cost. The lower the gauge (thicker the metal), the more expensive it is because it contains a greater material volume and because it is heavier, potentially requiring more installation cost due to the amount of supporting structure and labour to erect it palatably.

Read more: Metal Roof Cost Ontario in 2024: Online Calculator

Nevertheless, the investment in a low-gauge metal roof can be cost-effective in the long run. Higher thickness metal offers better cover, which means lower maintenance and lower risks of repair following extreme weather events. In contrast, thinner metal roofs are more affordable to install yet may need more maintenance or repair over time.

- Thicker metal = higher cost but long-term savings

- Thinner metal = lower upfront cost, may require more maintenance

Weigh initial investment vs. long-term benefits.

FAQs about steel measurements

- How is metal roofing gauge measured?

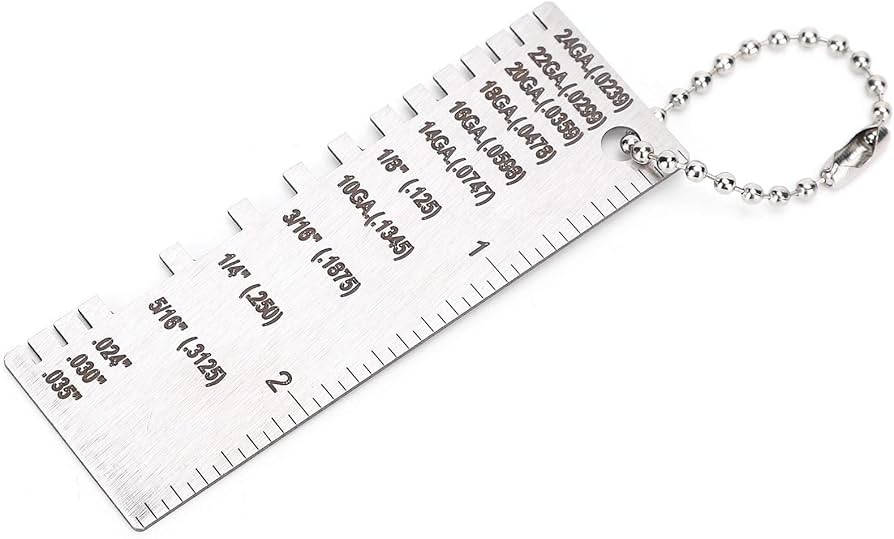

The thickness of metal roofing is measured in gauge. The metal is weighed and measured in 1/1000 of an inch. The lower gauging numbers show thicker metal while the higher digging numbers show thinner metal.

- Can I mix different GA. on one roof?

Will have some inconsistencies in the structure of your roof and the way they can respond differently to weathering and can cause inconsistency in the way your roof performs. You shouldn’t mix and match different gauges on the same roof.

- Does the gauge of a metal roof affect its soundproofing abilities?

The lower the thickness of the metal roof the better is the soundproofing. However, the important aspect in reducing the noise from rain or external sources is the insulation, not the gauge.

- Is a thicker gauge metal roof harder to install?

Yes, the thicker metal roofs are more difficult to install because they are heavier and require more hands and tools to install it properly and most likely cost more to install it compared to the thinner gauge.

- Are certain metal roofing better for specific types of buildings?

Yes, homes and other commercial buildings might use thicker gauges, say 22 or 24, because they need to provide more structural integrity against higher winds. At home, a 26 or 29 GA. is more common because they weigh less and therefore pose less cost. This depends on the part of the world, too. In regions where there are harsh winters, a thicker gauge might be required to withstand snow and the possibility of flooding.

- How does metal gauge impact energy efficiency?

The thickness of metal doesn’t affect energy efficiency – but thicker metal is overall more durable and able to be coated or finished with high-quality reflective surfaces or coatings for improved energy efficiency.

- Can a metal roof with a higher gauge (thinner metal) support solar panels?

Overall, yes, you can install solar panels on roofs that have a higher gauge metal, but you have to ensure that the roof structure is able to deal with the extra weight from the panels.

- Does the gauge of the metal roof affect its fire resistance?

No, the caliber of the metal is generally not that important because metal is an inherently fire-resistant material: the gauge of the metal doesn’t really make that much of a difference because the metal itself is noncombustible.

- Will a thicker metal roof increase my home’s resale value?

Similarly, a thicker metal roof can potentially increase the resale value, at least in areas of periodic extreme weather. Heavy metal roofing can be marketed as a long-lasting option that withstands excess precipitation and extreme heat or cold.

- How can I determine the gauge of my existing metal roof?

Figure the gauge of your metal roof with a micrometer (also called a feeler gauge), which is a gauge commonly used for measuring the thickness of metal. Have it checked by a roofing professional if you are not confident about gauging it yourself.

Conclusion

Choosing the right metal roofing is key to selecting the best roofing material for your house or business. The diameter directly affects the strength and durability of your roof, and consequently the cost of buying materials and installing the roof. A higher-scale roof is likely to cost more, withstand the worst weather extremes better, and suit the specific needs of certain building types. On the other hand, a lower-gauge roof will be less expensive, and might be perfectly adequate for your needs if you live in a mild climate and are looking for a less expensive roofing alternative.

Thicker types, such as 22 or 24 GA., offer greater durability and longevity, making them a good choice for industrial or commercial buildings, and also for homes in places with high snowfall, frequent winds or hail. Thicker metal often costs more up front, but can pay off in long-term savings when you factor in lower overall maintenance and repair costs. The thinnest sizes, like 26 or 29 GA., are the most affordable, easiest to install options. If you’re in a place with milder weather, these are a good option for residential buildings. However, they aren’t as protective as lower caliber options.

Read more: Top 10 Metal Roofing Companies in Ontario

With the above points in mind and the specific environment and structure of your building, we highly recommend that you seek the help of a professional Roofing Expert to help you with your decision-making as to what gauge roof you should select for your project to ensure you balance performance, longevity and cost for your roofing project. At Professional Metal Roofing we are always here to help guide you select the right gauge metal roof for your needs and home or building to ensure you have a great looking and long lasting metal roof on your property.

See our works

Giving you a sense of what a metal roof will look like in your home of commercial property