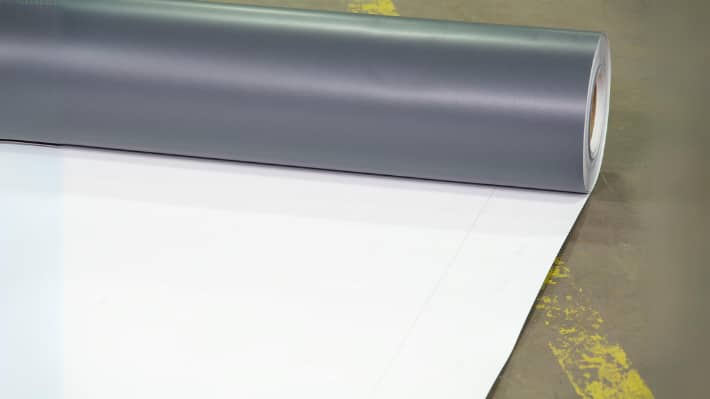

TPO Thermoplastic Polyolefin Roofing

Definition: TPO Thermoplastic Polyolefin roofing membranes represent single-ply solutions designed for flat and low-slope roofing installations. The combination of polypropylene and ethylene-propylene rubber provides TPO roofing with durable construction and weather-resistant properties while also achieving energy-efficient performance. Commercial and industrial roofing professionals frequently select TPO because it delivers excellent performance at a reasonable cost.

TPO Thermoplastic Polyolefin Key Characteristics:

- Single-Ply Membrane: The single-ply membrane features one waterproof layer that gets installed on insulation or a roof deck.

- Heat-Welded Seams: Heat-welded seams deliver maximum seam strength while blocking water from entering.

- Highly Reflective Surface: Reflective properties of the surface minimize heat absorption from sunlight which leads to reduced cooling expenses.

- Chemical and Puncture Resistance: The material protects against UV rays and resists damage from grease, oils and environmental pollutants.

TPO Roofing Thickness Options:

- A thickness of 45 mil (0.045 inches) is appropriate for light-duty purposes.

- In commercial roofing applications 60 mil (0.060 inches) TPO thickness meets industry standards.

- This 80 mil (0.080 inches) thickness delivers additional durability and protection against impacts.

Advantages of TPO Roofing:

- Energy Efficiency: White TPO membranes exhibit high solar reflectivity (albedo) which results in reduced heat absorption and subsequent reduction in cooling costs.

- Durability: The material withstands damage from punctures and tears as well as from chemical exposure.

- Flexibility: This material maintains its integrity by expanding when warm and contracting when cool which prevents cracking.

- Cost-Effective: TPO roofing presents similar advantages to PVC roofing while being less expensive.

- Eco-Friendly: The material can be recycled while containing no chlorine-based substances that are detrimental to the environment.

Disadvantages of TPO Roofing:

- Quality Variability: Certain manufacturers produce inferior TPO membranes which experience premature degradation.

- Seam Vulnerability: Heat-welded seams demonstrate strength yet improper installation creates potential seam failures.

- Shorter Track Record: TPO roofing material has been around for less time than EPDM and PVC roofing materials which leads to variable long-term performance across different brands.

Installation Methods:

- Fully Adhered: Direct adhesion to the insulation or roof deck gives the membrane enhanced wind resistance in the fully adhered installation method.

- Mechanically Fastened: Commercial roofs often use screws and plates to attach TPO membranes to the roof deck in mechanically fastened installations.

- Ballasted: The roof membrane is laid freely and secured with heavy ballast materials like gravel or pavers but this method is now rare.

TPO Thermoplastic Polyolefin Roofing Applications:

- Commercial Roofing: TPO roofing provides warehouses, office buildings, and retail stores with enhanced durability and improved energy efficiency.

- Industrial Facilities: The chemical resistance properties of this material make it perfect for industrial facilities like factories and manufacturing plants.

- Multi-Family Housing & Apartments: utilize TPO roofing systems designed for low-slope residential applications.

TPO roofing provides a flexible yet affordable roofing solution that improves energy efficiency for flat and low-slope roof applications. Building owners can achieve sustainable durability for both commercial and residential properties through correct TPO installation and maintenance.

See our works

Giving you a sense of what a metal roof will look like in your home of commercial property